|

Home | Project | Parts | Click for next page |

|---|

The metal was poured on Wednesday 20th December and the pack left to cool overnight. This picture shows the block with the exterior sand broken away to reveal the upper crankcase with all sprues still attached. Note - sprue is the channel through which the molten metal is poured, the vent through which it escapes and any solidified metal left from the process. |

|

Photographed from the front of the engine block. All of the internal voids are still full of sand and the casting flashes are clearly visible at all of the core joints. |

|

| The rear, nearside, three quarter view after trimming off the sprue. |  |

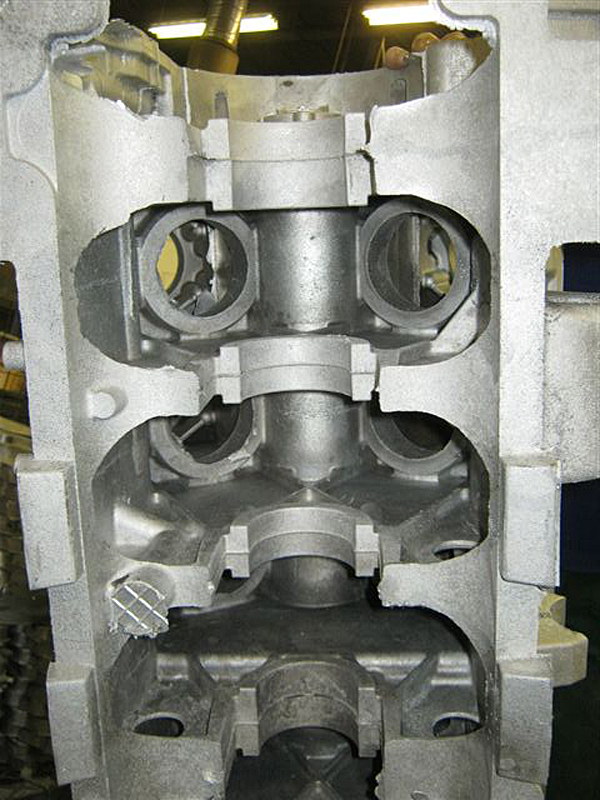

Looking from the rear. The accuracy of the liner cavities is evident and the cam wells and bridges in the centre of the block are clearly visible. |

|

Looking from the front. The camshaft bore at the top, idler gear plinth on the right and a straight view along the upper crankshaft bearing housings at the bottom. |

|

| Front to rear showing the upper crankshaft main bearing housings and the support webs for the walls. |  |

A slightly different angle showing the lower lands for the cylinder liners and the strengthening webs on the internal walls. |

|

| A close-up that shows the accuracy of the tool design. The vertical ridge running along the centre line is the underside of the camshaft well. |  |

|

© Copyright 2011-2015: Phantom Engineering Limited.