|

Home | Project | Parts | Click for next page |

|---|

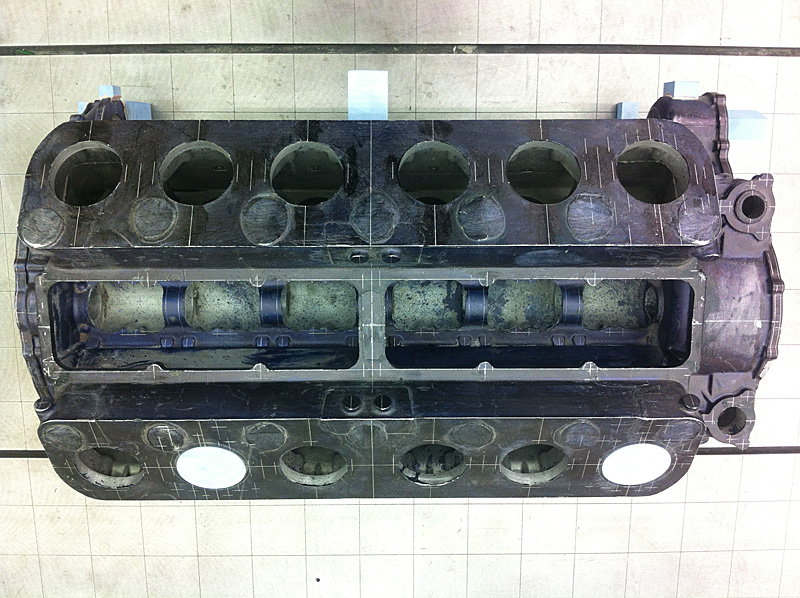

After cleaning the casting the exterior was covered in engineers blue. Pads were glued to the base, front and near side of the block and carefully machine to ensure that the block was perfectly square, in these three orientations, when placed on a surface table. |

|

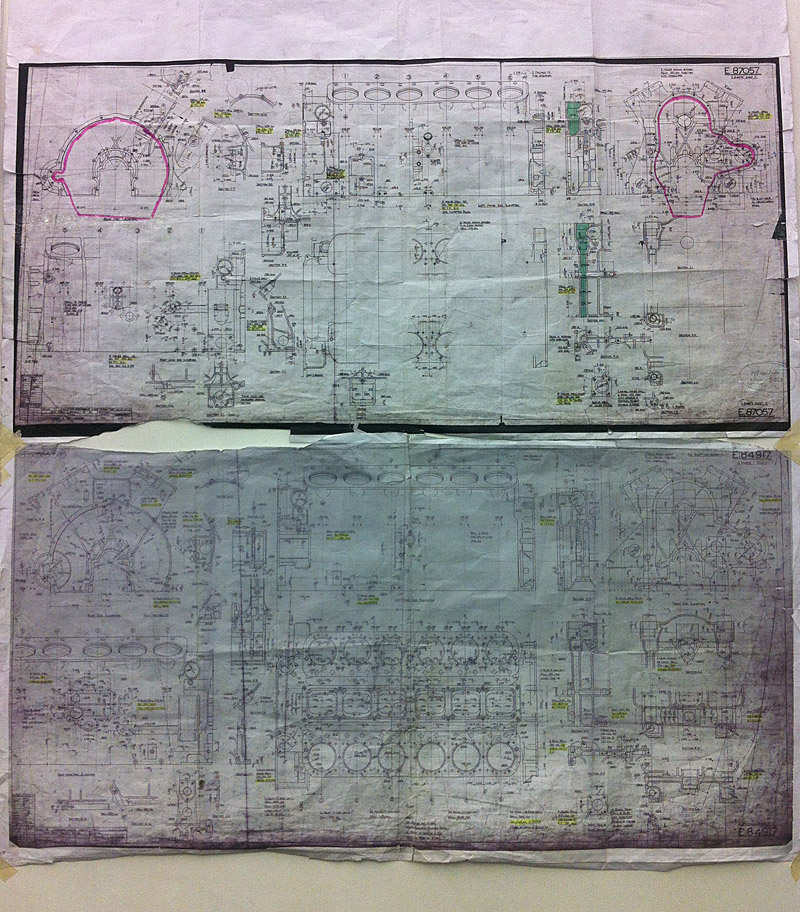

These are copies of original General Arrangement Drawings that contain most of the dimensional information. The prototype casting was marked up, as show in the adjoining photographs, by reference to the drawings and an original crankcase. The making up is done using a hard-tipped scribe with measurement made with extremely accurate engineers' rulers and gauges. The lines show datum points and component positions with the intersections being the coordinates for studs or drilled holes. The scribing exercise took over 50 man hours to complete. |

|

| The engine nearside with the front end at the top. The patterns were made slightly oversize to allow for material shrinkage during cooling plus an allowance of roughly 1/4" on all machinable faces. |  |

Careful examination shows that the casting was extremely accurate. Following on from this exercise the casting was subjected to detailed x-ray examination to scrutinise the accuracy and location of the internal walls and passageways.

|

|

© Copyright 2011-2015: Phantom Engineering Limited.